Processes

- Top Page

- Processes

MaruHachi offers a One-stop service from laboratory testing through prototype development to mass production, from Reinforcements to Prepreg materials and Preform materials

Not limited to onestop process, but flexible

Depending on your requirements and the resources you have, we can start with any process from matrix resin, reinforcement, prepreg or preform material.

MaruHachi's Processes

-

Prototyping and Development

We can handle everything from feasibility studies based on small-volume lab testing to development for mass production studies.

-

Mass Production / Quality Assurance

Building quality assurance system through initial flow study for mass production.

-

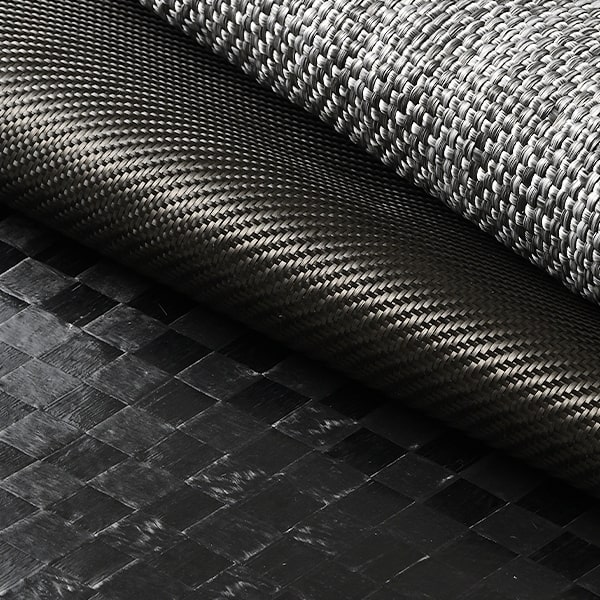

- Reinforcements Process

- We develop and manufacture products suitable for the requirements by utilizing fiber processing technologies such as woven and knitting technology.

-

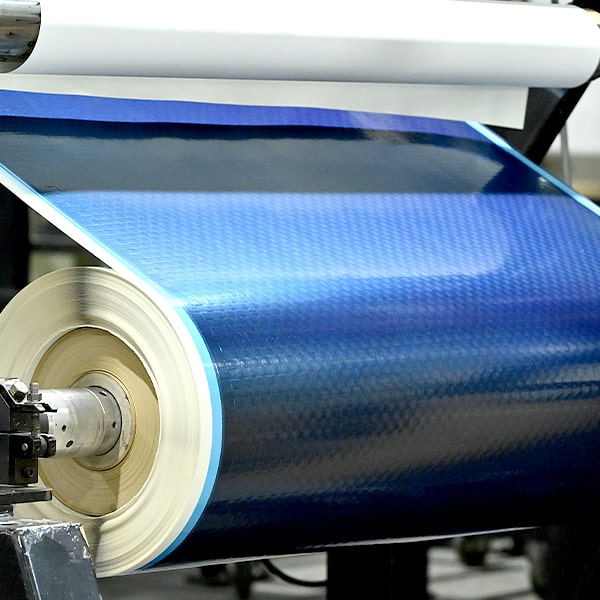

- Thermosetting Prepreg Process

- Original functionality can be added by designing formulations in-house, mainly using epoxy resins.(e.g., fire resistance, impact resistance, etc.)

-

- Thermoplastic Prepreg Process

-

The following matrix resins are available.

Middle-temperature type (melting point of 300℃ or less) engineering plastics: PA6, PC, TPU, etc.

High-temperature type (melting point of over 300℃ ) super engineering plastics: LCP, PPS, PEEK, etc.

-

- 2D Preform Process

- This is an intermediate material with a 2D shape.Laminates by press process

Tailored blanks by AFP process

-

- 3D Preform Process

- This is an intermediate profile with a 3D shape.Intermediate profiles with a simple shape by press process

Pipe shaped profiles and other layup profiles by AFP process

-

- Cutting Process

- Trimming and cutting by water jet process.Processing narrow tapes by slitting process

-

- Product Realization Support Process

- We also provide a product realization support process for each project, including evaluation testing, performance testing, data analysis , CAE simulation, and adhesive and bonding studies.

Onestop Process

-

Material Process

-

Reinforcements Process

Preparation processes include combining, twisting, warping and spreading processes.

We develop and manufacture the reinforcements in a combination suitable for your requirements. -

Prepreg Process

Thermosetting-type,

Thermoplastic-typeCombinations of 2 types of matrix resin system and 3 types of reinforcements are available. (e.g. fabrics, unidirectional UD, non-woven mat).

-

-

Preform Process

-

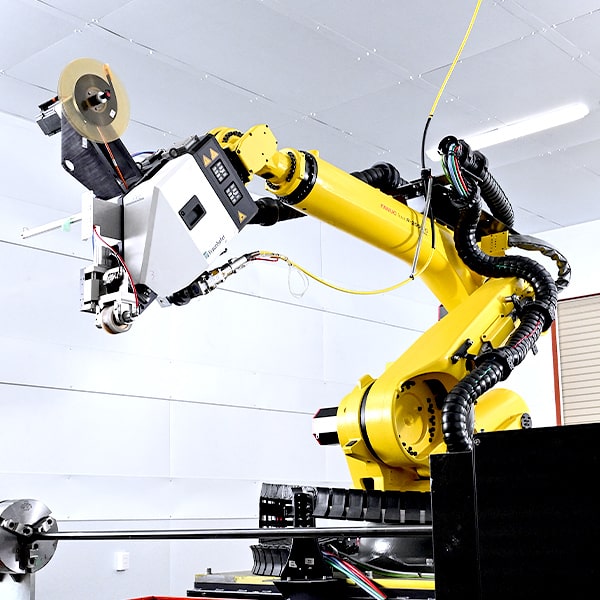

Layup Process

Arbitrary layup configurations with 0°, 90°, ±45° and ±30° are available.

This is a fully-automated layup system that can also be combined with fabrics, non-woven, core materials, etc. -

Tape Layup Process

Laser-asisted tape lay-up process for thermoplastic tapes.

The process is capable of 2D lamination, 3D easy shape processing, etc. -

Press Forming Process

Press forming process for Thermosetting types and Thermoplastic types (up to 430℃).

Press mxhine can be selected to suit the product size or development stage, from small presses to large multi-stage presses. -

Cutting Process

Post-processing of preforms, from trimming to shape cutting, Processes are selected to suit the application, such as water-jet cutting and slitting.

-

Contact

MaruHachi

Contact

MaruHachi

Feel Free to Contact Us

For More Information

Business Hour 9:00 - 17:00(JST)